A colour profile is just information that describes how a particular device, such as a scanner, computer monitor or printer, behaves with regard to colour. The three basic types are:

- input profiles, which describe the behaviour of devices such as cameras and scanners that capture colour information;

- display profiles, which define the colour characteristics of a television screen or computer monitor; and

- output profiles, which describe the behaviour of devices such as ink-jet printers.

Every machine that works with colour exhibits particular capabilities, characteristics and deficiencies. Each one has its own colour gamut, or range of colours, and none is absolutely linear. Raw images captured by the sensor of a digital camera may have a magenta cast under particular circumstances, and a printer with excellent mid-tone performance may block-up darker tones. If colour-handling devices were connected directly together, without any correction being made for their individual characteristics, prints emerging from printers would bear little resemblance to the original scene captured by a photographer.

To correct this situation it is basically necessary to establish a table of values which converts measured, displayed or generated colours into of the correct or standard colours. For a sensor that captures a magenta cast under particular circumstances, it might be necessary to apply an appropriate shift in towards green. The details of this correction would form part of the look-up table of colour values which constitute the sensor's colour profile. Of course it is not quite so simple in practice, but any colour profile performs basically this same simple function.

Input devices are profiled by measuring or working out the real RGB colour values of the original subject, and making appropriate corrections. Output and display devices are profiled, typically using a colorimeter, by calculating the values that must be fed in to generate the required colour. The profiles, represented by characteristic curves, are appended or tagged onto image files so that a profile-aware reading device will be able to correctly interpret the pixel values within the image.

Most modern, digital photographic equipment is supplied together with appropriate profiles to give the user a reasonable working start. However, it must be born in mind that such profiles are generic to the model rather than to a particular unit. Only experience will reveal how far manufacturing tolerances have moved a particular machine from its supplied profile. For the best results it is therefore necessary to profile all the specific units in a colour system.

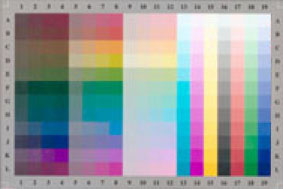

Creating a profile for an input device such as a scanner is relatively simple. A reference or target image consisting of a grid of precise colour patches is photographed or scanned. Profiling software then compares the recorded colour values to the known values of the standard colour patches, and creates an appropriate profile. This can then be saved as the default ICC profile for the relevant device or embedded in an image to provide context for its RGB values.

Creating a profile for an input device such as a scanner is relatively simple. A reference or target image consisting of a grid of precise colour patches is photographed or scanned. Profiling software then compares the recorded colour values to the known values of the standard colour patches, and creates an appropriate profile. This can then be saved as the default ICC profile for the relevant device or embedded in an image to provide context for its RGB values.

Profiling digital cameras is more difficult because the colour values recorded are dependent to a significant extent upon the nature of the lighting in which they were recorded. Consequently, a camera's profile is valid only for the particular lighting conditions for which it was created. This is more acceptable for a studio environment where lighting sources and colour temperatures remain relatively stable.

Monitors are profiled using a colorimeter suspended over the screen. Profiling software generates a series of accurately-controlled colour patches which are measured by the colorimeter. The colour values are compared with those generated by the software and a profile is obtained. This can then be installed as the default profile for a reasonable period of time.

Monitors are profiled using a colorimeter suspended over the screen. Profiling software generates a series of accurately-controlled colour patches which are measured by the colorimeter. The colour values are compared with those generated by the software and a profile is obtained. This can then be installed as the default profile for a reasonable period of time.

Printers are profiled by printing out a paper copy of a digital file defining a standard grid of colour patches. The type of paper, the resolution of the print, the colour settings and the inks are all significant and must be precisely as specified. The printed colours are then measured using a spectrophotometer. Profiling software compares the known values with those measured by the spectrophotometer and creates an appropriate profile. A similar process can be undertaken using a scanner or colorimeter to measure the printed patches, but the results are likely to be much less accurate.